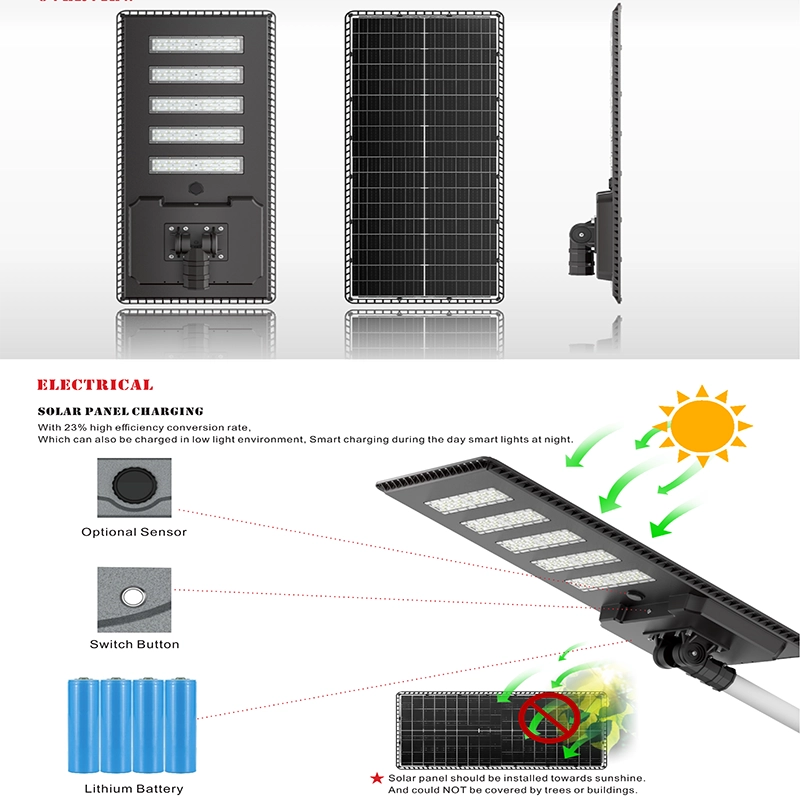

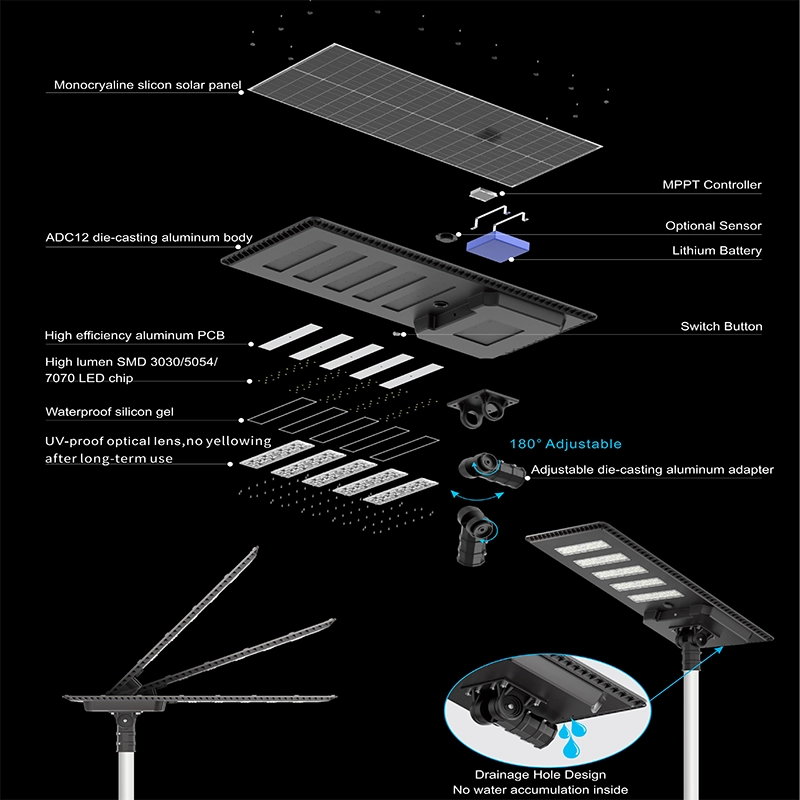

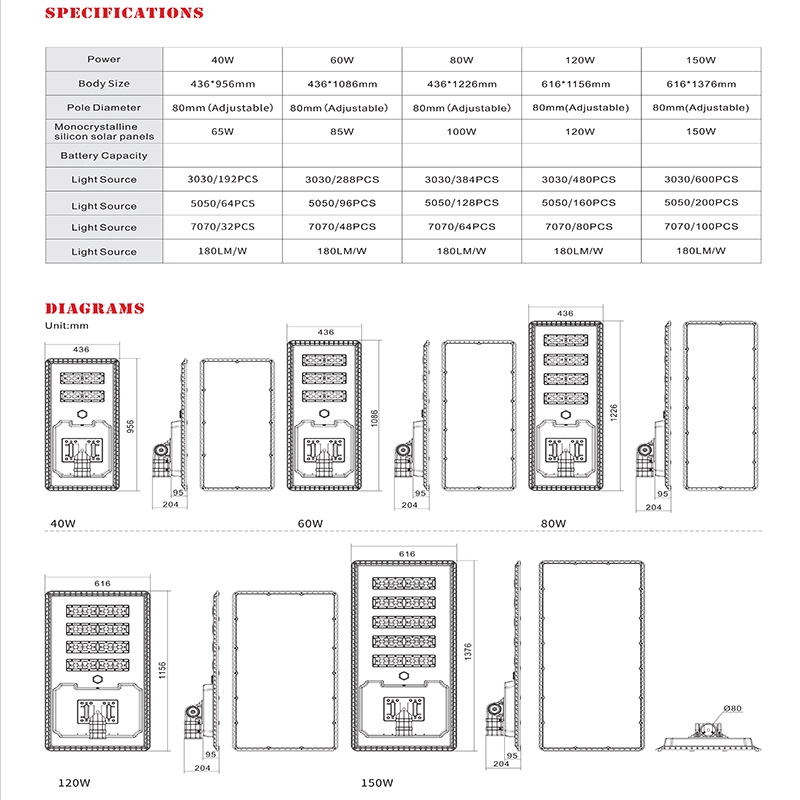

Die-Cast Solar Street Lights

WJDH Private Mold Series | ADC12 Aviation Aluminum

Level 16 Typhoon Resistance | IP66 Waterproof

WJDH Series Technical Gallery

Explore the structural details of our ADC12 Aluminum body.

Why Choose ADC12 Die-Cast Aluminum?

1. Integrated Molding

Unlike assembled plastic housings, our ADC12 die-cast body is formed in one piece. This provides Level 16 Typhoon Resistance and superior structural integrity for government projects.

2. Private Mold Advantage

The WJDH series is MCLsolar's exclusive design. Avoid price wars with common market models. Offer your clients a unique solar street light solution.

3. Ultimate Waterproofing

With high-precision die-casting, the sealing surface is perfectly flat. Combined with automotive-grade silicone rings, we guarantee a true IP66 Waterproof Rating.

WJDH Series - Engineering FAQ

Why use ADC12 Die-Cast Aluminum for solar lights?

What is the advantage of a Private Mold design?

Is this model suitable for coastal areas?

How do you ensure IP66 waterproof rating?

Can I customize the brand and specs?

What certificates do you have?

Zhongshan Chengyu New Energy Technology Co., Ltd

Global Leader in Intelligent Solar Lighting Solutions

12+ Years Exp | ISO9001 Certified | High-Tech Enterprise

Core Products

ISO9001 • ISO14001 • CE • RoHS • TUV • UL • IEC Certified Manufacturer