Street Light Poles Manufacturer

Hot-Dip Galvanized Q235 Steel

ISO9001 Certified Factory. 3m to 35m High Masts. Customizable for all Solar Street Light Projects.

Send Drawings for Quote20 Years

Anti-Rust Warranty

180 km/h

Wind Resistance

>86 μm

Zinc Thickness

ASTM A123

Galvanizing Std.

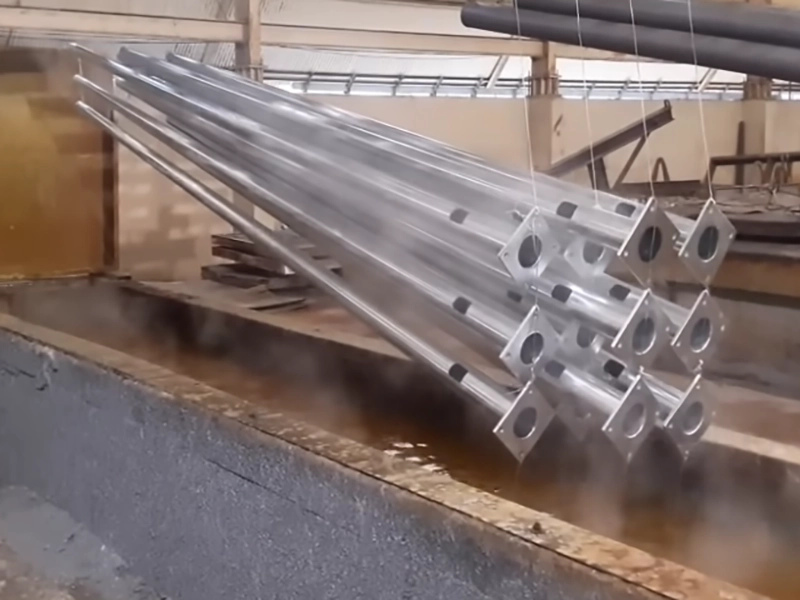

The Core of Quality: Hot-Dip Galvanizing

We strictly follow ASTM A123 / BS 729 standards. Immersed in 450°C molten zinc for internal & external protection.

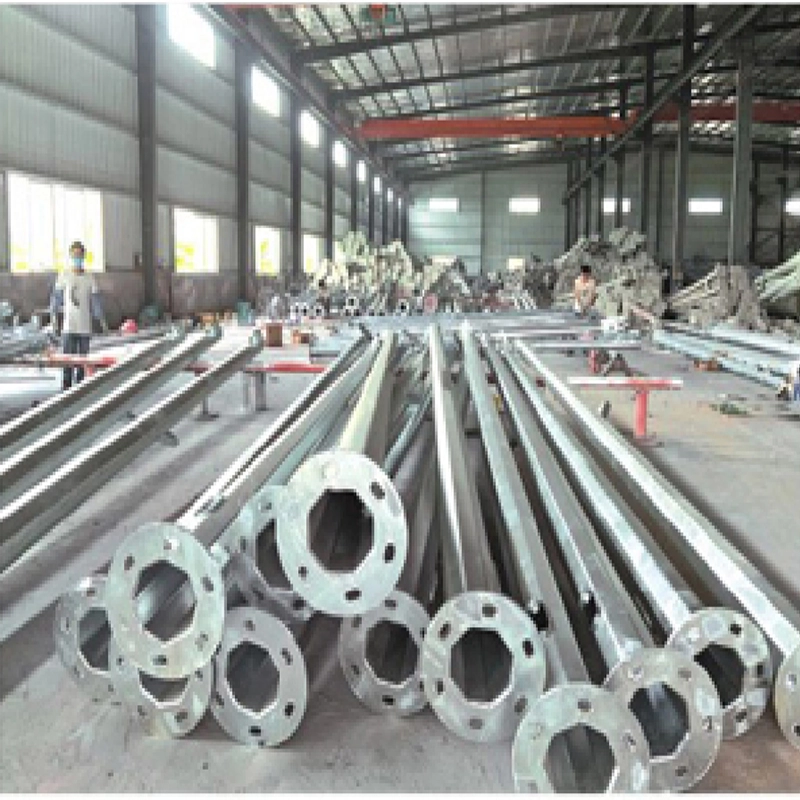

Advanced Production Line

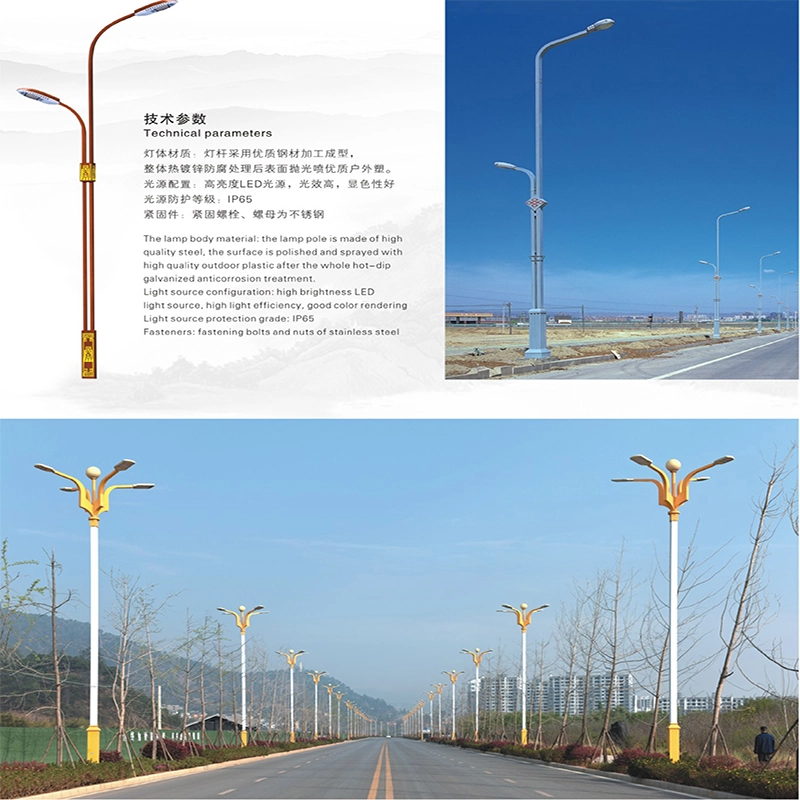

- Material: Premium Q235 / Q345 Steel plate from state-owned mills.

- Cutting: High-precision Laser Cutting for accurate dimensions.

- Welding: Automatic Submerged Arc Welding. Smooth lines, no cracks.

- Galvanizing: 100% Anti-corrosion treatment for harsh environments.

- Coating: AkzoNobel outdoor powder coating (RAL Colors available).

Factory Workshop Tour

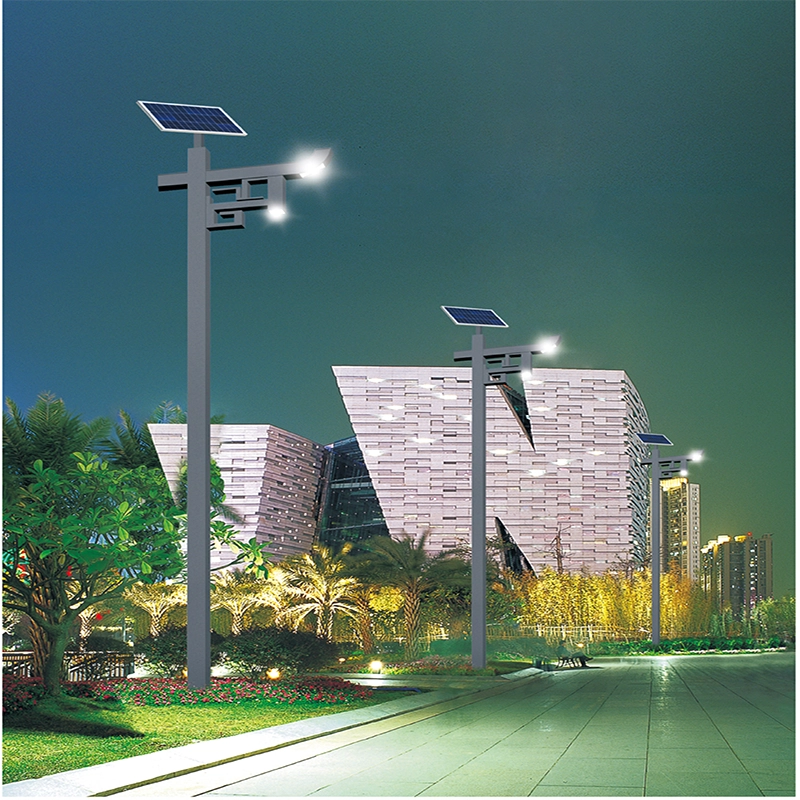

Customizable Pole Shapes

From 3m Garden Poles to 35m High Masts. Fully customizable for your project.

Single Arm Pole

Double Arm Pole

Octagonal Tapered

Conical Round

Square Tube

Solar Street Light Pole

High Mast Pole (20m+)

Traffic Signal Pole

Smart City Pole

Wind Resistant Pole

Save 50% Ocean Freight

Socket Nesting Loading

We use the smart "Socket Nesting" method (inserting small poles into large ones) to utilize every inch of the container.

- Capacity: Load 2x more poles per 40HQ container.

- Protection: Each pole wrapped in bubble film + felt cloth.

- Efficiency: Easy to unload with forklifts at the destination.

Technical Specifications & FAQ

| Specification | Standard / Options |

|---|---|

| Material | Q235 / Q345 / GR65 / SS400 High Strength Steel |

| Height Range | 3m - 35m (Customizable per drawings) |

| Wall Thickness | 2.5mm - 20mm |

| Shape | Conical, Octagonal, Hexagonal, Square, Polygonal |

| Surface Treatment | Hot-Dip Galvanized (ASTM A123) + Powder Coating |

| Wind Resistance | 120km/h - 180km/h (Designed according to location) |

Q: Do you help with pole design?

A: Yes! We can design the pole taper, flange size, and foundation cage based on your wind speed and solar panel weight requirements.

Q: What is the galvanizing standard?

A: We follow ASTM A123. The zinc thickness is >86μm (600g/m²), guaranteeing 20 years of rust resistance.

Q: Do you provide anchor bolts (foundation cages)?

A: Yes. Matching anchor bolts (foundation cage) are included. We can ship them early so you can pour concrete before poles arrive.

Q: Can you manufacture from my drawings?

A: Absolutely. As an OEM factory, we produce according to your CAD/PDF drawings, ensuring precise arm angles and flange holes.

Send Your Drawings for a Quote

Professional engineering team ready to support your project.

Zhongshan Chengyu New Energy Technology Co., Ltd

Global Leader in Intelligent Solar Lighting Solutions

12+ Years Exp | ISO9001 Certified | High-Tech Enterprise

Core Products

ISO9001 • ISO14001 • CE • RoHS • TUV • UL • IEC Certified Manufacturer